Timascus Bars For Sale

Choose by thickness or pattern

View all by: .050″ | .060″ | .070″ | .080″ | .090″ | .100″ | .110″ | .120″ | .130″ | .140″ | .150″ | .160″ | .170″ | .180″ | .190″ | .200″ | .220″ | .250″+

Timascus® Information

We sell Timascus with three kinds of patterning:

- Mosaic Patterned: The most expensive material we sell. The pattern goes all the way through the billet. This means the crisp lines and shapes do not wash out as you grind into the material.

Some mosaic billets take days to make. Often patterns require making a billet, then cutting and re-welding the billet together in a different way to get a new pattern. Every time the billet is re-welded there is a chance of a weld failure, which means scrapping the billet.

The billet must be machined flat before every re-weld. The machining turns the Timascus into worthless chips than cannot be reused. The worst case scenario is 80% of the original is lost. This means 10 pounds of titanium turns into a 2 pound billet when complete.

Some mosaic patterns like Racing Stripe & Pin Stripe look simple. It is just layers laid up and welded together. The hard part is keeping the layers straight. It takes extreme control on the forging press to weld the layers together without distortion. We call this “Precision Forging”. The layers in Precision Forged billets should not look like they were drawn by a 3 year old with a Sharpie pen.

- Single Pattern: The same pattern is on both sides of the billet. As you grind into the material, the pattern varies and is less defined. Most single pattern billets cost more than the double pattern and less than most mosaics.

Pattern welded metal has limits with regards to how deep it can be patterned, If you exceed the limit, the metal rips and/or delaminates.

Single pattern billets have the same pattern on both sides of the billet. This means the pattern is pressed in approximately 45% of the limit on both sides of the billet.

Single pattern Timascus is best when the customer will see both sides of the billet. Some examples are tools, jewelry, etc.

- Double Patterned: There are different patterns on each side of the billet. The pattern names are listed in the description. Double patterned Timascus billets are the least expensive billets available.

The primary pattern of the billet is listed first in the description and is the side photographed for the website. The primary pattern can be pressed into the billet as far as 80% of the metal yield limit.

The majority of the patterns on one side of the double sided billets are called Nebula. This pattern is created by the way the billet is forged. It is very organic and no two billets look the same. Nebula looks best when heavily contoured and sculpted. The pattern looks best when more layers are exposed. We do sell single pattern billets of Nebula.

Tips For Buying Pattern Welded Metals

The biggest problem with pattern welded metals is delaminations. A delamination is where the weld between the metals did not work. Here are a few points to consider when buying pattern welded metals.

Buy material from experts. An expert is someone that everyone else copies. We are the experts. We’ve been making pattern welded titanium since 2001. We know how to properly forge weld billets. Our return rate due to delaminations is .06% for 2018.

Never buy pattern welded material online unless there is a photograph of the actual material being sold. A sample photo is not acceptable. Think about the photos of fast food. When you get your fast food order, does it look anything like the photo?

Some of the imitators do show photos of the material they are selling. Delaminations and weld splits are clearly visible in the photos. Any delamination you can see in a photo goes deeper into the material.

Never buy pattern welded material that still has forge scale. This includes forge scale on the sides of billets. Machining the forge scale off reveals delaminations.

The video below is an example of our weld strength. The pattern is racing stripe. The Crescent wrench is 24”. The billet is bent more than 90°. There are no cracks, splits or delaminations.

opens in new window

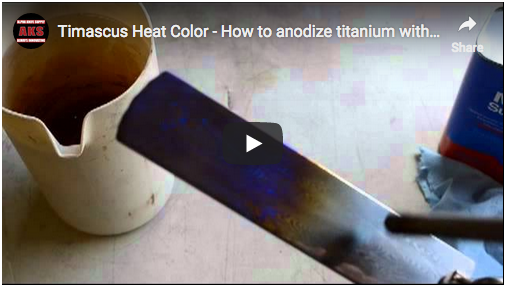

Coloring

Timascus can be colored by heat and/or anodizing. The current mix of alloys seems to show more contrast through the use of heat than anodizing. Although anodizing does show contrast in the higher voltage ranges. A highly polished finish will produce the brightest colors where as a satin finish can produce the most visually contrasting appearance. All of the current titanium coloring techniques can be applied to Timascus.

Working Characteristics

Timascus works virtually the same as other titanium alloys and we recommend you follow those guidelines. The one operation that is slightly different is in the milling of Timascus. Multiple types of titanium in Timascus result in different hardness throughout the barstock. The hard and soft areas cause wear on cutting edges of tools. We recommend using a round cornered cutter whenever possible. We found these tools held up better during machining.

Ultra Thin Timascus (UTT)

We’ve received multiple requests for ultra thin Timascus (UTT). We define UTT as billet thickness of .080” or thinner. The problem with UTT is keeping the billets flat. We try to get them as straight as possible, but there may be some minor curves.

opens in new window